Production

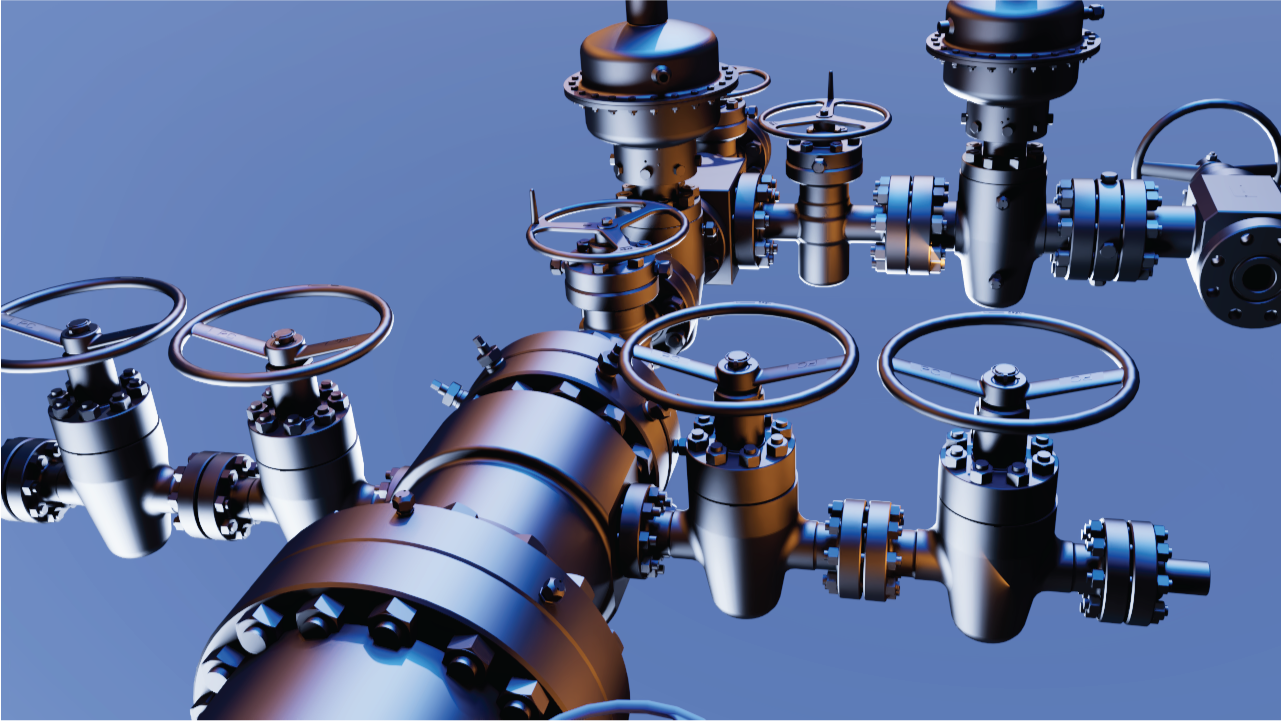

Achieving optimal performance during production is essential to your success. Vault remains resolute in our promise to deliver premium production equipment and service offerings, with an expansive supply of wellhead products available to help you safely and efficiently achieve all desired recovery rates over the life of the well. Vault’s vast inventory of API-approved production-related products offers a variety of trims, pressure ratings (3-15K psi), temperature ratings, PSLs, PRs, and connections required for the job.

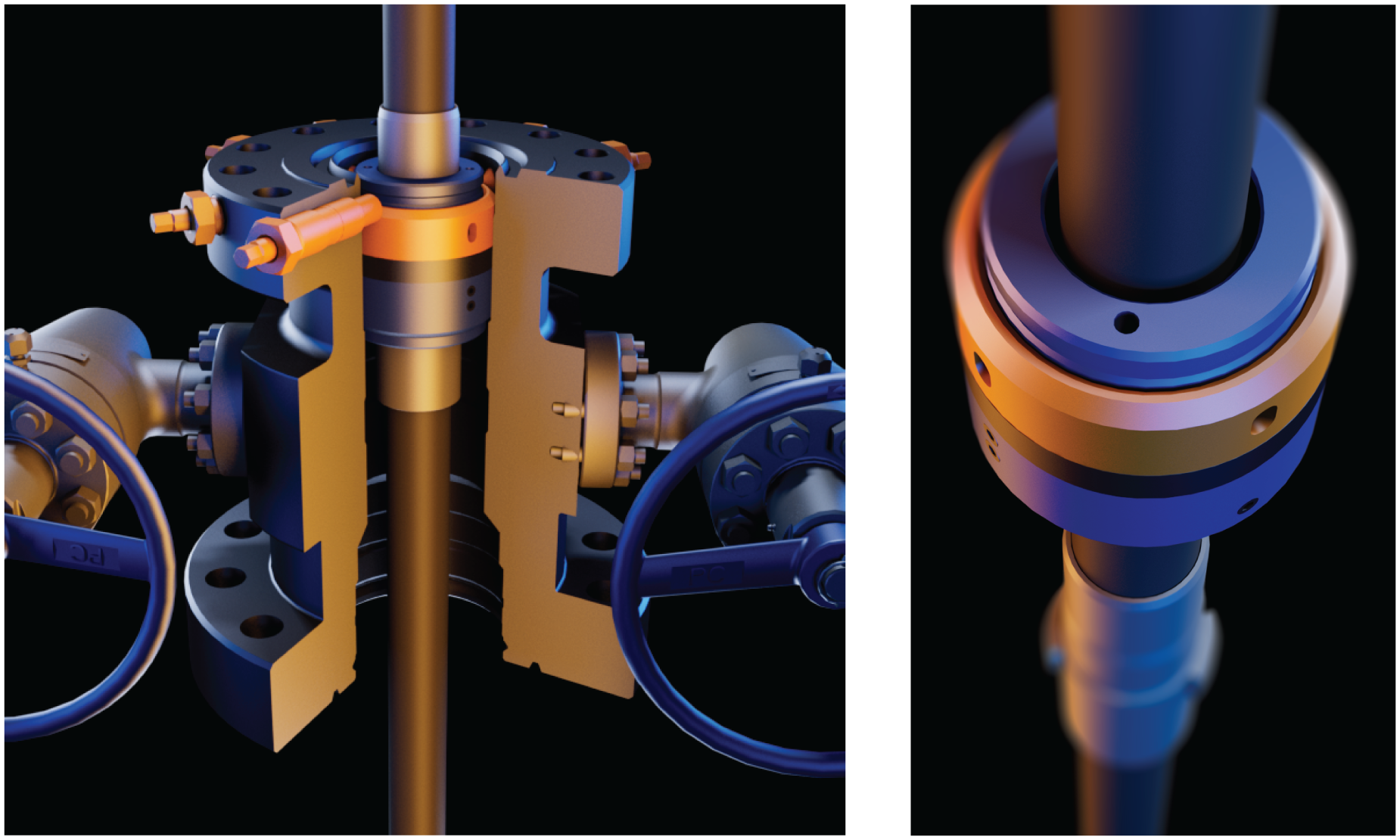

Vault’s pressure control equipment and expertise include our tailored height and function tubing heads, a wide selection of tubing hangers and adapters, fully pre-assembled and tested production trees custom-made to your specifications, specialty and engineered-to-order trees, hydraulic and manual valves, power feed-thru and ESP systems, safety shutdown valves, chokes, rod-lock BOPS, and more. See below for some of our featured products to help you safely execute on time and on target.

Tubing Heads, Hangers, and Adapters

Vault’s tubing head selection is second to none. Our API-certified tubing heads are offered in flanged and studded varieties in short, standard, and tall sizes. Utilize our mini tubing heads (MTH) for well profile reduction or extended height T-tubing heads to keep your wellhead below ground level during drilling and production lines accessible when you need them.

We have tubing heads, hangers, rod connectors, and adapters to accommodate single and dual-string tubing, control lines, injection, and artificial lift scenarios covering all stages of your well’s life. Inquire about our new T-LR pinless latch ring tubing head design.

T-LR “Pinless” Tubing Heads and Lock-Ring Tubing Hangers

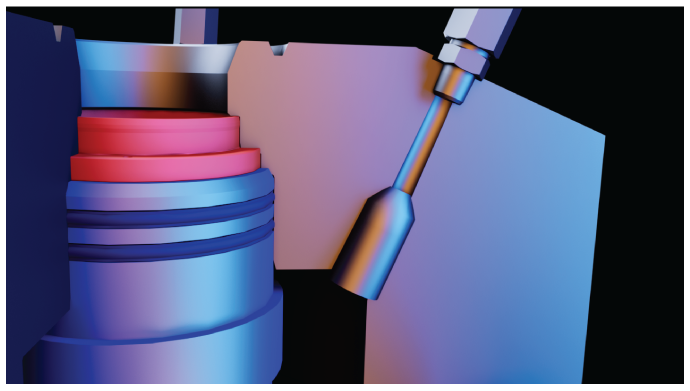

Improve safety and efficiency in your production operations. Vault PC’s T-LR Tubing Head and T-LR-EN Tubing Hanger combo use a lock-ring design to replace Lock Down Screws (LDS) typically associated with tubing heads. Similar to the casing hanger and packoff systems utilized in our casing head assemblies, this “No” LDS design eliminates potential leak paths, dangers of operating LDS under pressure, and pressure releases resulting from human error.

The T-LR system also offers the ability to set and lock (or unlock and retrieve) the tubing hanger through the BOP on a single trip, reducing time in the cellar and NPT resulting from making up and disengaging locks crews. The run tool provides mechanical verification of full lock ring engagement, and sealing areas can be accessed and tested after the hanger lock ring is engaged. LR heads and hangers connect to tree assemblies using standard VPC tubing head adapters. No special adapters are required.

Tension Latch “Bayonet” Tubing Hangers

Stop worrying about changing hangers for each step of production. Vault’s two-piece tension left-hand latch “bayonet” hangers allow customers to run the hanger as an extended neck tubing hanger in both T and TCM bowl profiles during standard tubing production. However, this system simultaneously offers the capability to unlatch the internal mandrel from the hanger body allowing operators to lower the tubing below ground level to set anchors or packoffs in tension through the BOP while retaining complete well control.

Vault PC’s bayonet hangers offer the same capabilities as bushing-style hangers with the increased safety of never requiring the technician’s hands to be exposed to dangerous pinch-point areas below the hanger, rendering this unnecessary safety risk obsolete. Additionally, the inner mandrel has a type H Back Pressure Valve (BPV) thread, and a 2-way check can be set in the hanger after pulling rods during workovers to test BOPs before pulling tubing. Special application options include continual control line (CCL), high-capacity weight and working pressures, and right-hand latch designs.

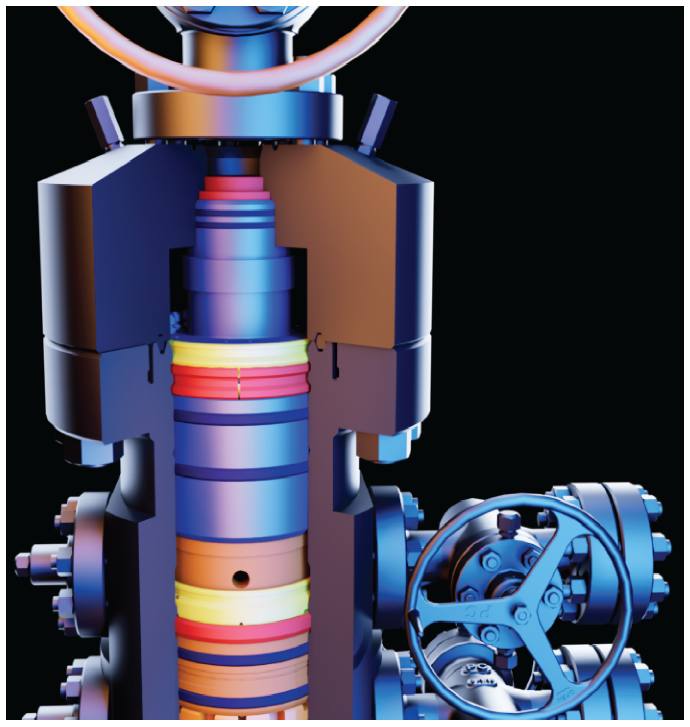

RSH Production Tubing Hanger with Lock Ring Packoff

Utilizing the upper bowl of our RSH multi-bowl, Vault’s production tubing hanger provides a mechanically energized lock ring packoff, omitting the need for casing head lock-down screws and tubing heads altogether for certain operations. Reduce cost, minimizing installation times and NPT. Improve safety and efficiency by reducing time in the cellar. The inward bias ring is mechanically engaged by a singular tool that can both set and retrieve the tubing hanger. Use a VG-42 seal-compatible tubing head adapter to frac directly through production equipment for 10K frac. CCL (Continuous Control Line) hanger options are available.

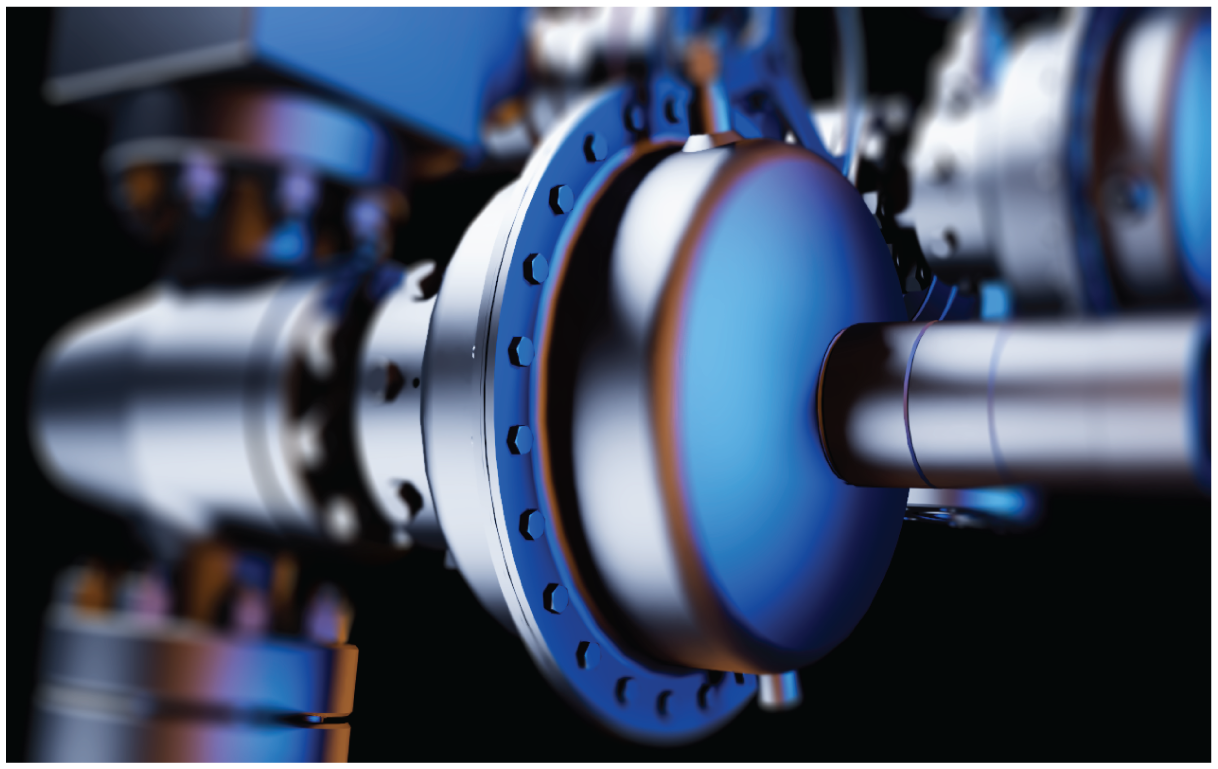

4-1/16” 5M/10M CCL Tubing Head Adapter

Utilize our RSH CCL Production Tubing Hanger with our improved 4-1/16” 5M/10M CCL Tubing Head Adapter. All include a replaceable metal-to-metal-tubing hanger neck seal with a testable connection and an oversized control line port to improve mobility and reduce accidental damage to control lines during installation and removal operations.

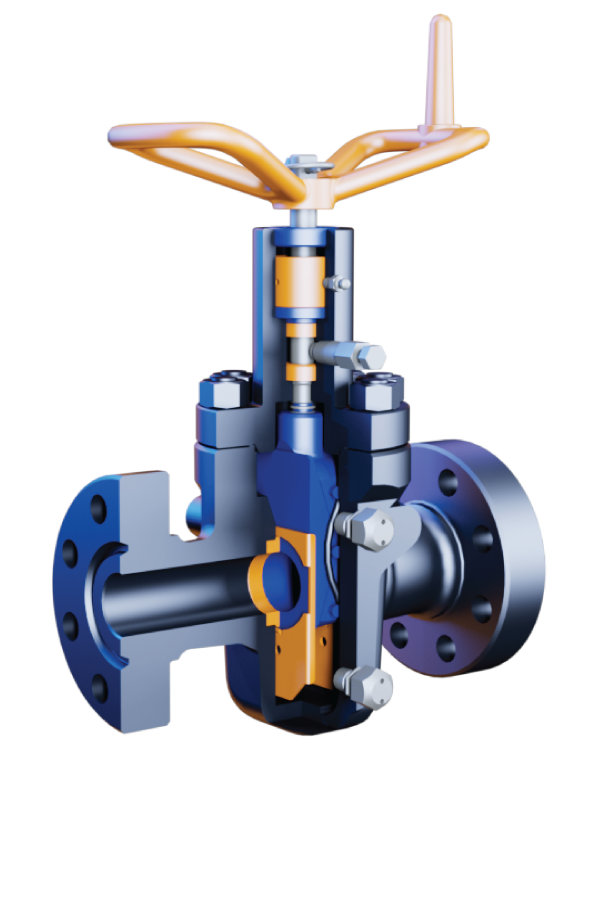

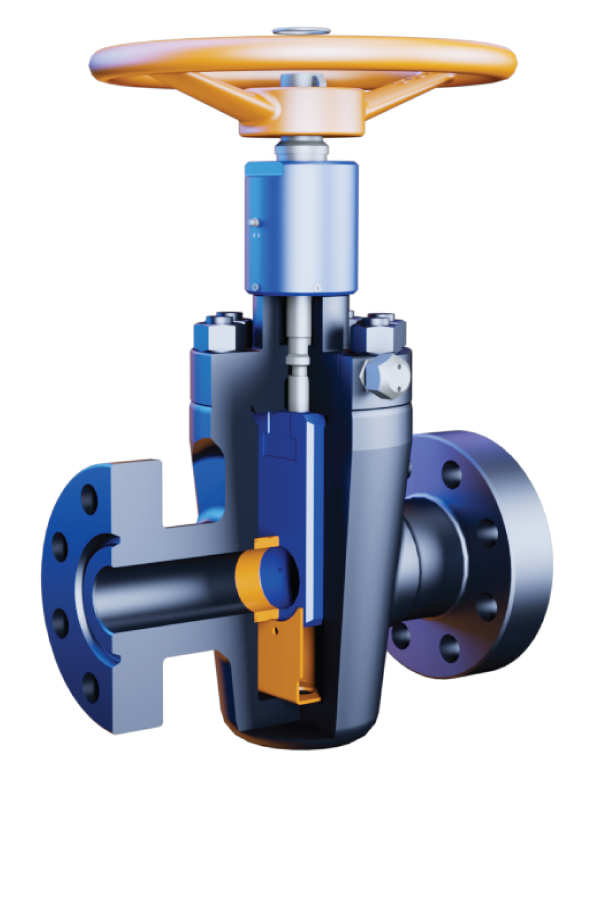

API 6A Gate Valves

Vault Pressure Control has an extensive catalogue of API 6A gate valves available for use during production and other phases of the well. We carry wedge (expanding) gate and slab gate valves. We offer manual and hydraulic gate valves and the full spectrum of bore sizes, trim classifications, and temperature, pressure, trim, PSL, and PR ratings.

Pneumatic Diaphragm Actuated SSVs

Safety shutdown “Fail-safe closed” valve for use in onshore and offshore applications to control wellbore and pipe fluids and hydrocarbons. Requires sufficient supply pressure to open and maintain actuator opening pressure. Available in a variety of bore sizes (1-13/16” to 5-1/18”), pressure ratings (2-15K psi), and temperature and trim classifications.

VPC NoBolt MACH ESD Self-Contained Hydraulic Actuator

Comprehensive self-containment ǀ Horizontal or vertical actuator orientation capable ǀ Manual open and close mechanism ǀ No flowline pressure, gas, or electricity required

Experience our newest evolution in safety shutdown valves. The Vault PC No Bolt MACH actuator, fitted with a self-contained hydraulic control system, provides a safe and efficient fail-safe open and close for emergency shutdown operations in severe climactic conditions and remote operations with no external power. The unique modular actuator design provides unparalleled fluid management, enhanced reliability, and improved shop and field installation and serviceability, with all components independently replaceable (if necessary).

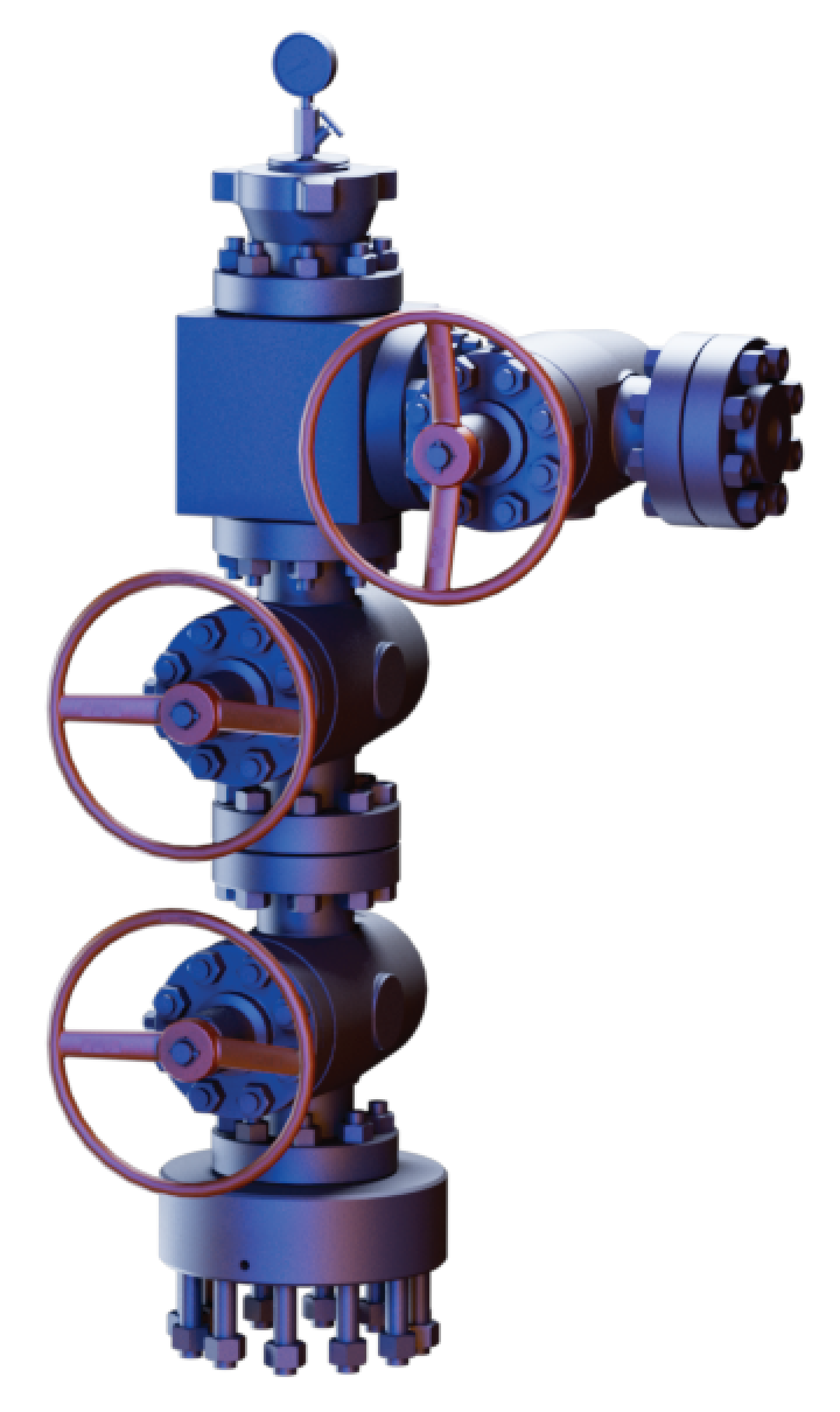

Production Trees

Vault has a large selection of hangers, adapters, valves, and flange connections to allow you to create the production tree (Christmas tree) assembly you need to support your operations. Whether you need to connect to rods or tubing, injecting chemicals, need CCL connections, or lift with an ESP, we have the assembly to fit your well. With our broad assortment of valves, we will ensure your well pressure is safe for your operational needs. Click below to connect with a Vault specialist to discuss your operation’s requirements.

Salt Water Disposal (SWD)

With the increased need for safe and environmentally sustainable produced water management and increased regulatory compliance required, be assured your wellhead has the correct corrosion resistance to keep our environment safe and reduce unnecessary NPT and future costs resulting from unforeseen equipment replacements. Vault offers a variety of valve sizes, trim levels, adapters, configurations, and coated and non-coated options for different levels of corrosion requirements.

Specialty Equipment

At Vault, we work with our customers to design products to suit their specific needs, such as the high-pressure, high-temp tree (pictured here) and the pinless LR tubing head design. Additional specialty product successes include geothermal, carbon capture, gas mitigation, salt water disposal, ESD, mobile on-site testing systems, and more. In our rapidly changing industry, sometimes “off the shelf” is not an option, so click the button below to connect with a VPC wellhead equipment specialist and work with Vault’s engineering team to create the products needed to take your operations to the next level.